Biodiesel

Ultrasonics Processing Applications

Ralsonics is a leading Indian manufacturer of advanced ultrasonic systems designed for high-efficiency biodiesel production and industrial cleaning. With decades of expertise in sonochemistry and ultrasonic process engineering, Ralsonics delivers solutions that accelerate transesterification, enhance mixing and reaction rates, and ensure superior cleaning of biodiesel production equipment.

Whether you are a small-scale biodiesel producer or a large industrial plant, Ralsonics’ ultrasonic reactors, processors, and cleaning systems help you achieve higher yields, cleaner operations, and reduced processing costs.

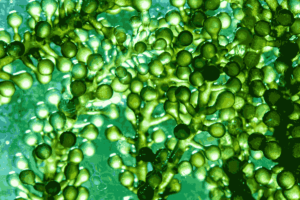

Biofuel Industry

Biodiesel production depends on effective mixing, transesterification, and purification processes. Traditional mechanical stirring or batch reactors often deliver slow reaction rates, inconsistent yields, and require high energy inputs.

Ultrasonic technology, both for biodiesel production and equipment cleaning has become a powerful solution to improve efficiency, reaction quality, and overall yield.

Ultrasonics is used for:

- Accelerating biodiesel synthesis reactions

- Enhancing mixing of oil and methanol

- Improving transesterification efficiency

- Removing contaminants from biodiesel equipment

- Degassing and filtering biodiesel

“Ultrasonic biodiesel processing using Ralsonics’ sonicator helps provide a significant improvement in yield”

Why Ultrasonic Technology Is Important in Biodiesel Production

Speeds Up Transesterification

The intense cavitation created by ultrasonics dramatically accelerates the chemical reaction between oil and methanol, reducing processing time from hours to minutes.

Achieves Better Mixing at Molecular Level

Ultrasonic waves create micro-emulsions, ensuring methanol, oil, and catalyst are uniformly dispersed.

Increases Biodiesel Yield

More complete reactions lead to:

- Higher biodiesel output

- Lower unreacted oil content

- Better conversion efficiency

Reduces Catalyst Requirement

Cavitation enhances reactivity, allowing a reduction in catalyst usage by 30–60%, reducing production cost.

Improves Biodiesel Quality

Ultrasonics leads to:

- Lower free glycerin

- Reduced soap formation

- Clearer, cleaner biodiesel

- Faster phase separation

Impact of Ralsonics’ ultrasonic processors in the biofuels industry

Applications

Ultrasonic processing can be used for the following applications:

- Ultrasonic mixing of oils and fats with methanol

- Ultrasonic disintegration of cellular structures and intracellular material extraction from grains used for fermentation

- Ultrasonic disintegration of organic waste

Bearings

|

Crankshafts |

Carburetors |

Hydraulic coolers

|

Differential Case |

Oil coolers |

Shafts |

Pistons

|

Air Conditioning Parts |

Inlet manifolds |

Brakes |

Gears |

Mirrors |

Diesel Injectors |

Fuel injectors |

Engines

|

Radiators |

Steering assemblies |

Turbochargers |

Engine Blocks |

Torque converters |

Gearbox components |

Valve bodies |

Compressors |

Dampers |

Transmission Systems |

Cylinder Heads |

Filters |