Cosmetics

Ultrasonic Processing Applications

Since the last 20 years, Ralsonics has been manufacturing ultrasonic processors for developing new applications in emerging sectors. With Ralsonics, you can develop the required process for your application with the help of our lab scale processors. We will then help you scale up to industrial scale processors that are designed for your specific process. Ralsonics’ industrial processors have hundreds of applications, all of which lead to cost savings, higher quality products and increased productivity.

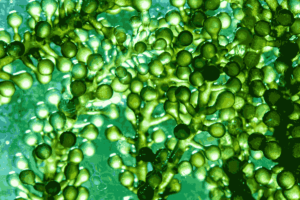

Cosmetic Industry

Cosmetics is an important component of the FMCG industry. With the advent of social media, fashion consciousness has reached new heights and sustained growth in the cosmetics industry is expected. Considering that cosmetics are directly applied to human skin, there can be zero compromises on quality. Ultrasonic processing is essential to improve the quality of most cosmetic products.

“In the manufacturing of cosmetics, Ralsonics’ probe sonicators are used in sonochemistry and ultrasonic extraction”

Impact of Ralsonics’ ultrasonic processors in the cosmetics industry

Applications

Ultrasonic processing can be used for the following applications:

- Homogenization

- Dispersion and distribution of pigments and powders in liquids

- Production of stable emulsions

- Nanoparticle formation via milling

- Gentle extraction of antioxidants

- Encapsulation in liposomes

- Incorporation of titanium oxide and zinc oxide nano-suspensions

Short list of products typically produced using Ralsonics’ ultrasonic processors

Creams |

Oils |

Lotions |

Balms |

Serum |

Gels |

Waxes |

Sunscreens |

Lipstick |

Nail Polish |

Mascara |