Aerospace

Ultrasonic Cleaning Applications

Since 1973, Ralsonics has been supplying ultrasonic cleaning equipment of all sizes spanning 15 industries. Our equipment is known for its reliability. We fully understand the requirements and processes of our customers before specifying any equipment for use. Due to over four decades of experience in ultrasonic cleaning, we have learned and developed best practices for cleaning components in each industry.

Aerospace industry

Safety is a critical factor in the aerospace industry. We understand that the cleanliness levels of your components have a direct impact on the safety of thousands of people flying in aircraft using your components. Even small traces of grease and particles left behind on aircraft components can lead to disastrous consequences. Aircraft parts must be cleaned routinely to ensure that they are in the pristine state they were when first manufactured. Furthermore, all aircraft parts need to meet more and more stringent safety requirements.

However, manual cleaning and handling of these parts is very labor-intensive and expensive. With ultrasonic cleaning technology, all these parts can be cleaned by fully automated systems in a matter of minutes.

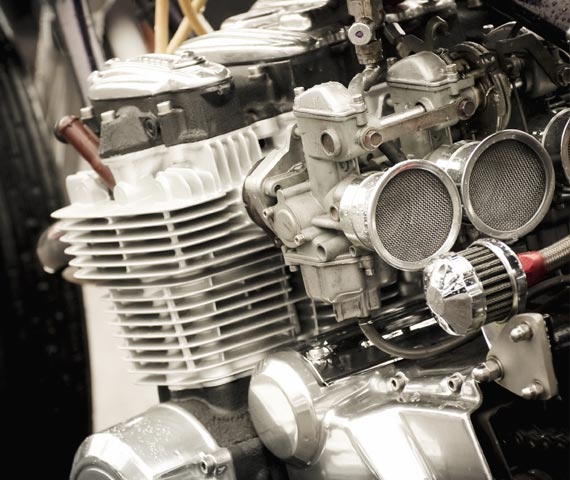

Ralsonics’ ultrasonic cleaners are well known in the industry to provide ultra-fast and thorough cleaning for aerospace components ranging from fuel nozzles to engines. Ralsonics has a large range of products (multistage cleaners, emission free vapor degreasers, ultrasonic cleaners), catering to every possible component that needs to be cleaned in the aerospace industry.

“The only solution for precision cleaning of components for aerospace manufacturing and MRO is ultrasonic cleaning”

Impact of Ralsonics’ automated cleaners in the aerospace industry

How to transition to ultrasonic cleaning?

More often than not, it is not possible to disrupt an existing assembly line. In such cases, we can provide solutions to add ultrasonics to existing assembly lines.

In the aerospace industry, objects to be cleaned have a clearly defined process and requirement. As a result, the available cleaning time in an assembly line is well-defined. An automated ultrasonic cleaning system will do the cleaning job much faster than any cleaning technique. As a result, a cleaning station can easily be added without changing the rest of the production processes.

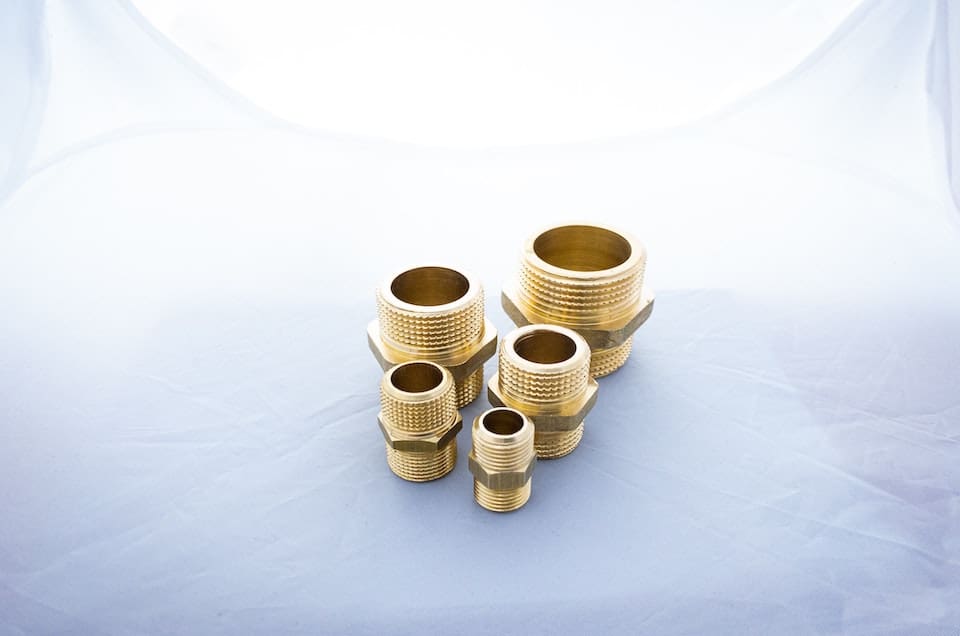

For regular maintenance, a number of aerospace parts must be cleaned before further use. Typically, these parts are immersed in cleaning chemical tanks to remove all the contamination. Ultrasonics can be retrofitted to these tanks. This leads to faster cleaning and reduced chemical usage.

Applications

Ultrasonic cleaning can be used for the following applications:

- Pre-Cleaning, intermediate cleaning and final cleaning of new parts during manufacturing

- Cleaning of old parts for regular maintenance and repair

- Cleaning before coating

- Pre and post FPI cleaning.

- Oxygen supply line cleaning

- Exotic material cleaning

- Aqueous and solvent cleaning and drying.

- Surface engineering and coating.

- Emission free degreasing.

Here is a short list of parts that are typically cleaned using Ralsonics’ ultrasonic cleaners

Airfoils |

Turbine blades and vanes |

Engine components |

Injectors and fuel nozzles |

Landing gear like wheels |

Pneumatics |

Hydraulics

|

Actuators |

Brakes |

Bearings

|

Exhaust Shrouds |

Generators |

Electronics

|

Fragile items like glass |

Filters |