Engineering

Ultrasonic Cleaning Applications

Since 1973, Ralsonics has been supplying ultrasonic cleaning equipment of all sizes spanning 15 industries. Our equipment is known for its reliability. We fully understand the requirements and processes of our customers before specifying any equipment for use. Owing to over four decades of experience in ultrasonic cleaning, we have learned and developed best practices for cleaning components in each industry.

Engineering industry

The engineering industry is a very diverse industry serving thousands of applications ranging from consumer goods to support for other sectors. The primary use of ultrasonic cleaning in this industry is to ensure a consistent and repeatable cleaning process. The engineering industry requires dependable and long lasting machinery.

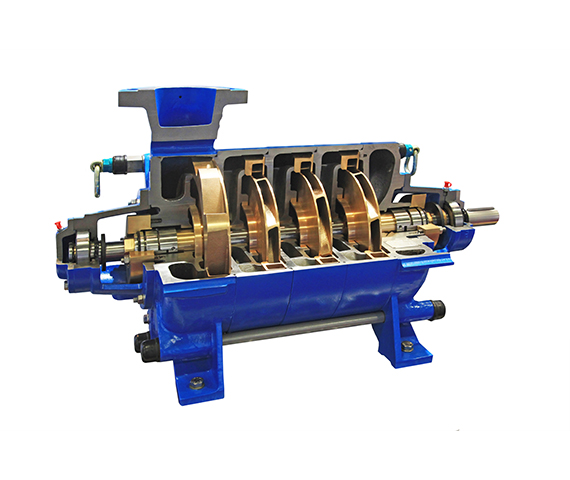

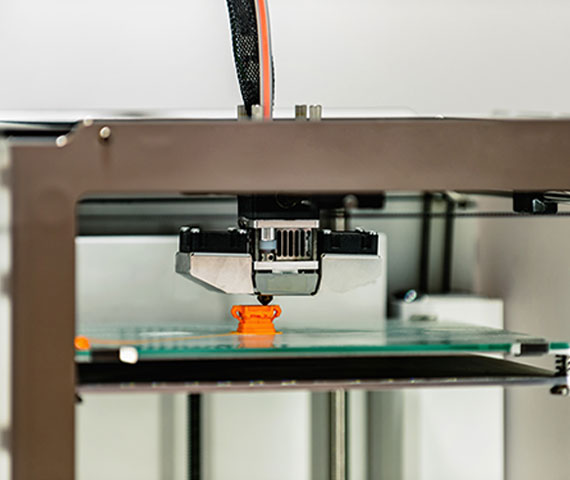

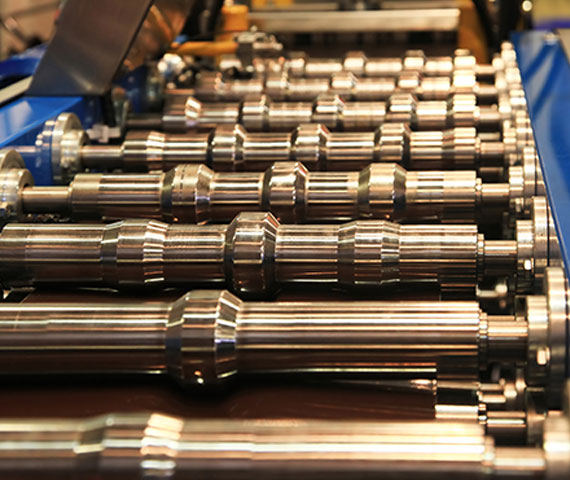

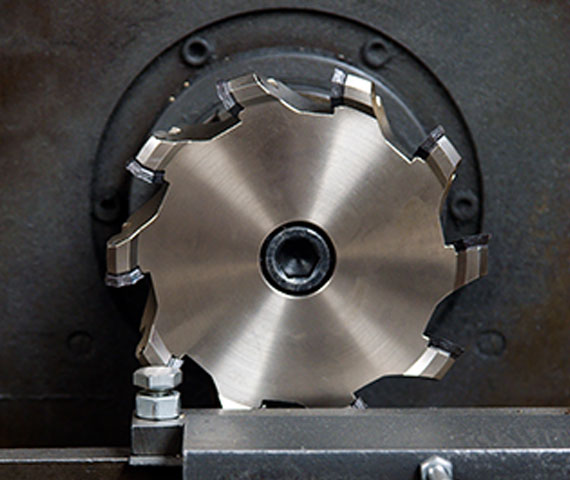

Typically the engineering industry requires cleaning of machined parts in removal of any contamination, especially in hard to reach areas of components. Furthermore, before finishing processes like plating, anodizing, coating etc. pre-cleaning with ultrasonics ensures much better adherance of the coating layer leading to longer life. Mold cleaning is another common application in this industry for regular cleaning of mold release and opening blocked exhaust vents.

Ralsonics’ ultrasonic cleaners are well known in the industry to provide ultra-fast and thorough cleaning for engineering components ranging from screws to engines. Ralsonics has a large range of products (multistage all-purpose cleaners, emission free vapor degreasers, ultrasonic cleaners), catering to every possible component that needs to be cleaned in the engineering industry.

“Electronics manufacturers in India use Ralsonics’ ultrasonic machines for PCB cleaning”

Impact of Ralsonics’ automated cleaners in the engineering industry

Applications

Ultrasonic cleaning can be used for the following applications:

- Pre-Cleaning, intermediate cleaning and final cleaning of new parts during manufacturing

- Machined parts cleaning

- Pre-cleaning for finishing applications like plating, anodized, coating etc

- Thorough cleaning of oil, scale, dirt, grime, carbon

- Oxygen line cleaning

- Emission free degreasing

- Cleaning of old parts for regular maintenance and repair

- Fully automated cleaning and handling

- Cleaning and drying pre- and post-dye penetrant examination

Here is a short list of parts that are typically cleaned using Ralsonics’ ultrasonic cleaners

Plastic injection molds |

Extrusion dies and molds |

Gears |

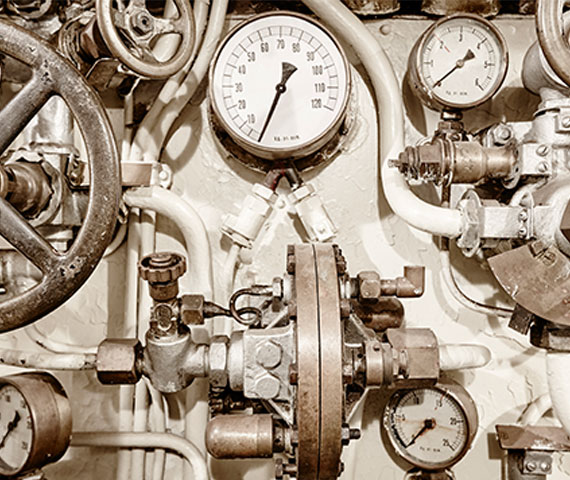

Valves |

Ball bearings |

Pumps |

Heat Exchangers |

Printing components |

Anilox rollers and sleeves |

Tools

|

Rivets |

Fasteners |

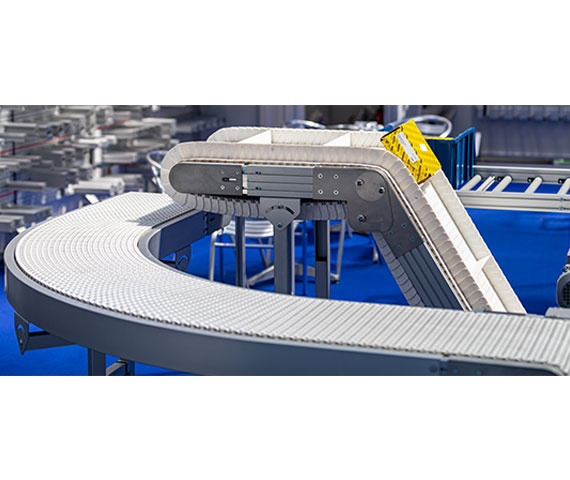

Rollers

|

Punches |

Cutters |

Conveyors

|

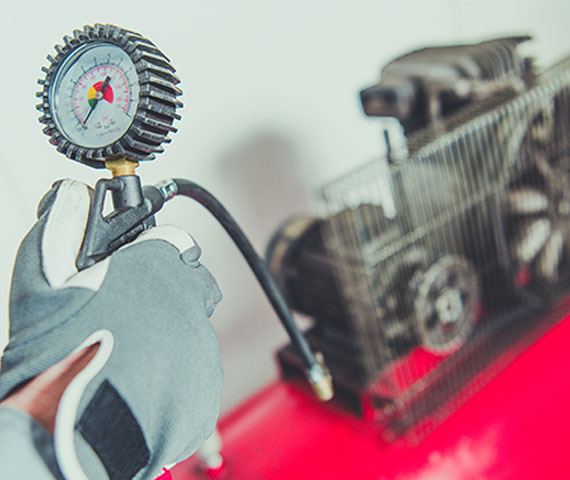

Compressors |

Adhesive gun components |

Measuring devices

|

Watches |

Jewellery |

Optics

|

Kitchen Sinks |

Kitchen Tools |

Sprinkler Heads

|