07 Oct Ultrasonic Tube Resonators Are the Ultimate in Industrial Cleaning

Reading Time: 2 minutesAn organized manufacturing plant that uses effective cleaning equipment is often more productive, efficient, and safer than one that is not. Therefore, the cleaning equipment and methods used in these places must be nothing less than the best.

Ultrasonic cleaning is perhaps the most suitable for cleaning a wide range of materials, such as metals, glass, rubber, ceramics and even some hard plastics. It is especially useful for cleaning complex items with blind holes, cracks and recesses and removing closely adhered contaminants from them.

Cleaning with better efficiency.

The use of cleaning equipment has come a long way over the years. Robots have replaced primitive cleaning tools, and technology is now a priority in the cleaning industry. These developments have given rise to inventions that have become an essential part of cleaning.

One such invention is Ralsonics’ ultrasonic tube resonators that are the current state-of-the-art in ultrasonic cleaning. Specially designed for demanding environments, these resonators are more powerful than any other form of ultrasonics and offer high throughput and efficient cleaning.

360-degree oscillation

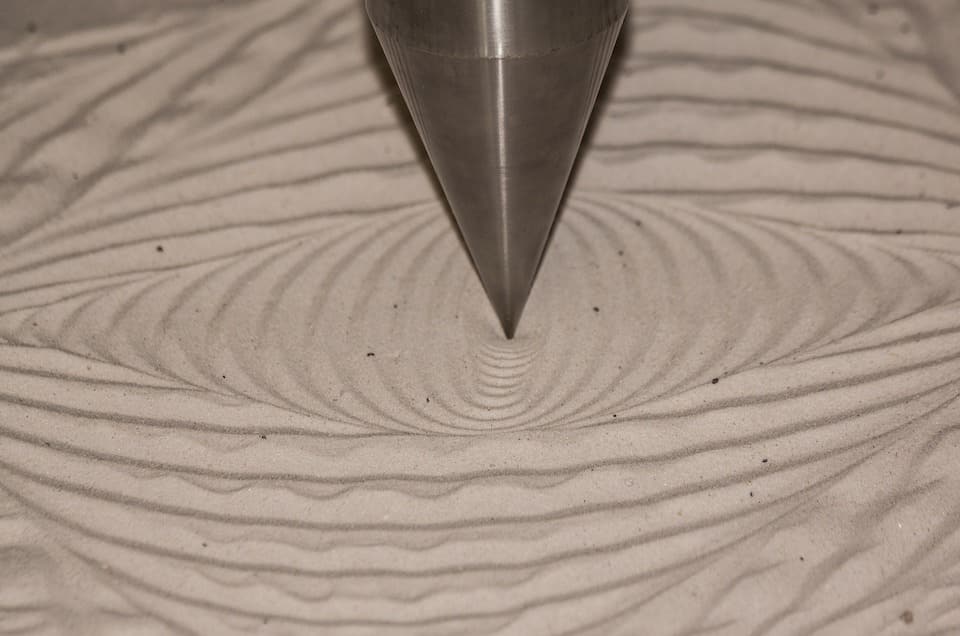

Unlike traditional transducers, the ultrasonic tube resonator emits ultrasonic waves at 360 degrees, providing omnidirectional transmission of ultrasonic power. The emitted waves reflect against the tank wall, rebounding cavitation and crisscrossing its direction to create an intensive and homogeneous ultrasonic vibration field for cleaning tanks.

Simple and robust

Ralsonics’ tube sonicators are only 1/5th the size of traditional immersive ultrasonic boxes and are easy to install and remove. Their low weight and volume also make them ideal for installation in constricted places. You can mount them in any direction (as long as they are immersed in water) and retrofit them into existing ultrasonic systems.

You can install these sonicators in vacuum or high-pressure vessels without worrying as they are resistant to harsh environments. Their robust and durable design also gives them a lifespan that is three times more than traditional resonators.

Unhindered efficiency

The tubular cleaner is versatile due to its various installation lengths and can produce a series of acoustic powers that range from 300W to 1200W per resonator. As a single generator drives the tubular cleaner, it has a unique sweeping frequency that supports optimal cleaning.

You can rest assured that there will be no loss of reaction force when it comes to Ralsonics’ ultrasonic tube resonators, as both the force and reaction force remains within the water. This also prevents substantial loss of energy.

Unmatched applications

Ralsonics’ tube resonators find ultrasonic applications in a wide variety of industries. For example, the steel industry utilizes tube resonators to clean and coat steel sheets. Apart from this, heavy engineering industries also use them to clean heat exchangers.

Unlike other ultrasonic cleaning tools, tube resonators offer more effective cleaning in industries like medical, automobile, aerospace and plating which require thorough cleaning of delicate items like surgical instruments, engine components and intricate tools.

You can consider these ultrasonic tube resonators an investment to help you obtain highly efficient cleaning at reduced costs. So, contemplate replacing your old immersible bricks and tank mounted transducers with Ralsonics’ latest tube resonators to improve your parts cleaning.

No Comments