30 Mar Ultrasonic Cleaners for Cleaning Injection Molds

Reading Time: < 1 minutes

In any manufacturing unit, it is important to maintain every part or tool that is used

on daily basis to avoid failures. Especially if the machine is expensive, one can not

afford to be careless with maintenance. But, annual maintenance is the only factor

that needs to be considered in a long run? No! There are other small factors that

help in extending your machine’s life. If these factors are considered and taken into

account at regular intervals it will benefit the manufacturers.

This blog will be sharing one of the prominent factors in maintaining your machine. And as the title suggests, we will be discussing the importance of cleaning the molds and the most effective way to do it.

Depending on the mold's design, elements such as temperature changes, opening and shutting the mold, ejector pin motion, and other actions can all lead to mold breakdown over time.

Although a good injection mold will be built to withstand this wear and tear, unanticipated events can still happen as a result of the numerous stresses.

Hence it is important to clean the injection molds at regular intervals to increase efficiency and reduce the timing of annual maintenance. And one doesn’t need to stress how important these two factors can be for the long run and work efficiency.

There are numerous ways that are practiced for cleaning these molds but they have their own set of drawbacks. The most effective and faster way to clean the mold is by ultrasonic cleaners.

Ultrasonic cleaning revolves around the process called cavitation, the implosion of billions of microscopic air bubbles against surfaces immersed in a cleaning solution. Generator-powered transducers attached to the underside of a stainless steel tank produce bubbles.

The implosions blast loose and carry away contaminants on any surface immersed in the cleaning solution. The process is fast, and safe, and does not damage products that can be safely immersed in a water-based cleaning solution.

Cleaning injection molds on a regular basis is necessary to remove all burned-on deposits from the surface and any leftovers without harming the tool There are endless types of injection molds that can be cleaned using Ultrasonic cleaners.

Along with that, there are additional benefits ultrasonic cleaners can provide:

Mentioned below is the process of cleaning heat exchangers using Ultrasonic Cleaners

Ralsonics have been manufacturing industrial cleaning machines for over 49 years! With rich experience in technology and innovation, engineers at Ralsonics will help to choose the best and most convenient Ultrasonic cleaners as per your requirement. Why delay when you can contact us today!

This blog will be sharing one of the prominent factors in maintaining your machine. And as the title suggests, we will be discussing the importance of cleaning the molds and the most effective way to do it.

Why it is necessary to clean the injection molds?

Depending on the mold's design, elements such as temperature changes, opening and shutting the mold, ejector pin motion, and other actions can all lead to mold breakdown over time.

Although a good injection mold will be built to withstand this wear and tear, unanticipated events can still happen as a result of the numerous stresses.

Hence it is important to clean the injection molds at regular intervals to increase efficiency and reduce the timing of annual maintenance. And one doesn’t need to stress how important these two factors can be for the long run and work efficiency.

Ways to clean your injection molds

There are numerous ways that are practiced for cleaning these molds but they have their own set of drawbacks. The most effective and faster way to clean the mold is by ultrasonic cleaners.

Ultrasonic cleaning revolves around the process called cavitation, the implosion of billions of microscopic air bubbles against surfaces immersed in a cleaning solution. Generator-powered transducers attached to the underside of a stainless steel tank produce bubbles.

The implosions blast loose and carry away contaminants on any surface immersed in the cleaning solution. The process is fast, and safe, and does not damage products that can be safely immersed in a water-based cleaning solution.

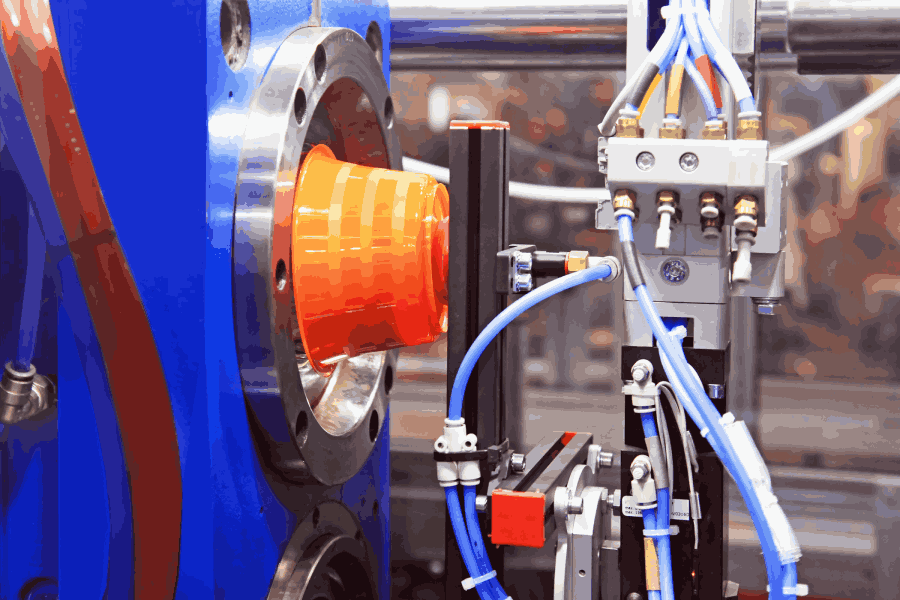

Cleaning injection molds on a regular basis is necessary to remove all burned-on deposits from the surface and any leftovers without harming the tool There are endless types of injection molds that can be cleaned using Ultrasonic cleaners.

Along with that, there are additional benefits ultrasonic cleaners can provide:

Mentioned below is the process of cleaning heat exchangers using Ultrasonic Cleaners

- Removes dirt without damaging the complex mold pattern

- Reduction in labor cost

- Increases the product’s commercial viability because more end users require a certain degree of cleaning.

- Eliminates remaining burnt substances

- Achieves a uniform cleaning that is difficult to achieve with manual cleaning.

- Makes your workplace more productive and speeds up the mold changeover procedure.

Ralsonics have been manufacturing industrial cleaning machines for over 49 years! With rich experience in technology and innovation, engineers at Ralsonics will help to choose the best and most convenient Ultrasonic cleaners as per your requirement. Why delay when you can contact us today!

No Comments