10 Oct High-Powered Cleaning for Big Engines

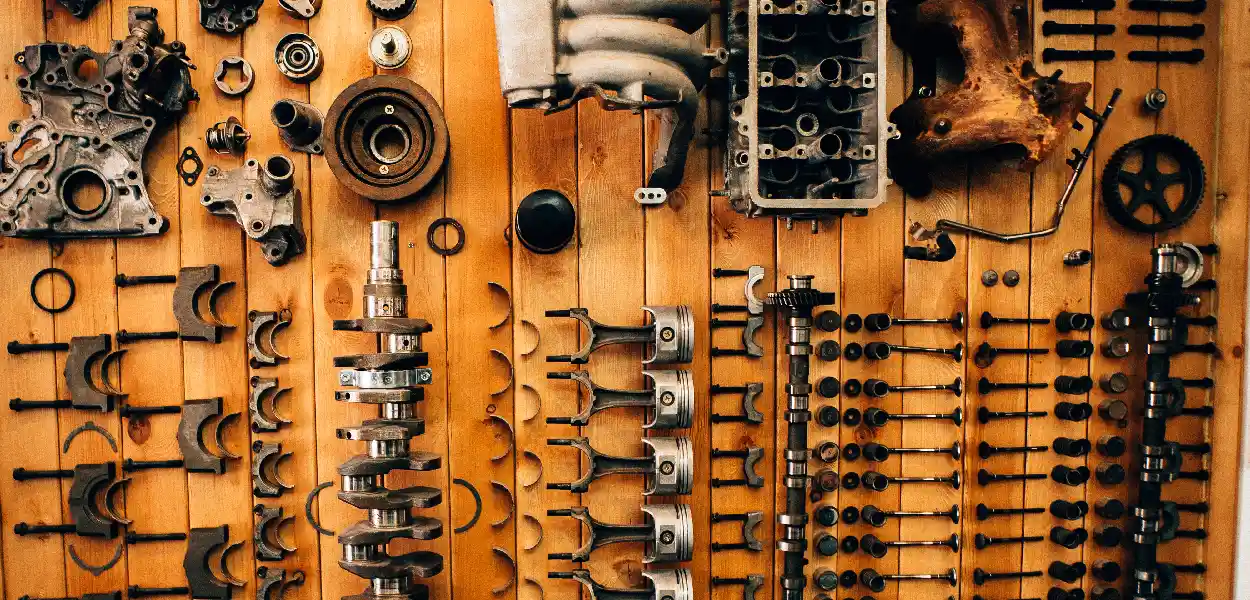

Reading Time: 4 minutesIndustrial engines are the lifeblood of various sectors, powering everything from manufacturing plants to transportation systems. However, over time, these engines accumulate dirt, grease, carbon deposits, and other contaminants, leading to decreased efficiency, increased emissions, and costly maintenance. Traditional cleaning methods often fall short when it comes to large industrial engines. This is where ultrasonic cleaning solutions step in, offering an efficient and environmentally friendly way to maintain and restore these critical assets. In this comprehensive guide, we will explore the world of ultrasonic cleaning solutions for large industrial engines, diving into their principles, benefits, applications, and best practices.

Understanding Ultrasonic Cleaning

Ultrasonic cleaning involves the use of high-frequency sound waves, typically above the range of human hearing (above 20,000 Hz), to agitate a cleaning solution. These sound waves create millions of tiny bubbles through a process called cavitation. When these bubbles collapse, they generate high-energy microjets that dislodge contaminants from the surfaces of objects immersed in the cleaning solution. This mechanism allows for the removal of even the most stubborn dirt and contaminants without the need for an abrasive scrubber.

Advantages of Ultrasonic Cleaning for Large Industrial Engines

- Precision Cleaning

Ultrasonic cleaning provides a level of precision that traditional cleaning methods simply cannot achieve. The microscopic bubbles created during cavitation can reach intricate and hard-to-reach areas of engine components, ensuring thorough cleaning.

- Reduced Labor Intensity

Large industrial engines comprise numerous components, some of which can be massive and unwieldy. Ultrasonic cleaning eliminates the need for manual scrubbing and labor-intensive cleaning processes, reducing human effort and associated costs.

- Environmentally Friendly

Unlike some harsh chemical cleaning methods, ultrasonic cleaning typically uses water-based detergents that are safer for the environment. Additionally, it minimizes the generation of hazardous waste, contributing to sustainability efforts.

- Increased Engine Efficiency

Clean engines run more efficiently. By removing contaminants like carbon deposits, rust, and grease, ultrasonic cleaning can help restore an engine’s performance, resulting in reduced fuel consumption and emissions.

- Extended Engine Lifespan

Regular ultrasonic cleaning can extend the lifespan of large industrial engines by preventing the buildup of damaging contaminants and corrosion. This translates to significant cost savings over the long term.

Applications of Ultrasonic Cleaning for Large Industrial Engines

- Automotive Industry

Large engines in heavy-duty vehicles, such as trucks, buses, and construction equipment, benefit from ultrasonic cleaning. It helps maintain engine components like injectors, pistons, and cylinder heads, ensuring optimal performance and compliance with emission standards.

- Marine and Aerospace

Ship engines and aircraft turbines often have intricate components that require meticulous cleaning. Ultrasonic cleaning is used to remove salt deposits, corrosion, and other contaminants, enhancing the reliability and safety of these critical systems.

- Manufacturing

Manufacturing facilities with large industrial engines, such as power generators and industrial pumps, use ultrasonic cleaning to keep their equipment in top condition. Clean machinery is more reliable, reducing downtime and production losses.

- Energy Sector

Power plants and facilities with large engines for electricity generation rely on ultrasonic cleaning to maintain turbines, compressors, and other vital components. Clean engines improve energy efficiency and reduce operational costs.

- Rail Transport

Ultrasonic cleaning plays a crucial role in maintaining locomotive engines and railway equipment. It ensures that trains operate smoothly and meet safety and emission standards.

Best Practices for Ultrasonic Cleaning of Large Industrial Engines

- Proper Equipment Sizing

Ensure that the ultrasonic cleaning equipment is appropriately sized for the size and volume of the engine components to be cleaned. Oversized equipment may lead to unnecessary energy consumption, while undersized equipment may result in inadequate cleaning.

- Selecting the Right Cleaning Solution

Choose a cleaning solution that is compatible with the materials and contaminants you are dealing with. Consult with cleaning solution suppliers to find the best formulation for your specific needs.

- Temperature and Time Control

Maintain proper control over the cleaning temperature and duration. The ideal settings may vary depending on the cleaning solution and contaminants. A temperature that is too high can damage sensitive components, while a cleaning cycle that is too short may not yield the desired results.

- Pre-Cleaning and Post-Cleaning Inspection

Perform a thorough inspection of the engine components before and after cleaning. This helps identify any damage or wear that may require further attention.

- Regular Maintenance

Ultrasonic cleaning equipment itself requires regular maintenance to ensure optimal performance. Follow the manufacturer’s recommendations for cleaning and maintaining transducers, generators, and tanks.

Ultrasonic cleaning solutions offer a powerful and efficient method for maintaining and restoring large industrial engines. With their precision, reduced labor intensity, and environmental benefits, they have become a valuable asset in various industries, from automotive and manufacturing to aerospace and energy production. By following best practices and investing in the right equipment, organizations can ensure that their large industrial engines remain efficient, reliable, and cost-effective, ultimately contributing to enhanced productivity and sustainability.

Ralsonics has been in business with ultrasonic technology for over 49 years. Ralsonics provides a full array of vacuum dryers, vapor degreasers, ultrasonic resonators, ultrasonic cleaners, and ultrasonic sonicators. With the company’s ability to design and build its own equipment, the products can be customized to meet specific requirements. Why the delay? Contact Us today!

If you enjoyed reading this blog and would like to read more of our blogs, here are our top recommendations:

No Comments